Welcome to COOL INNOV

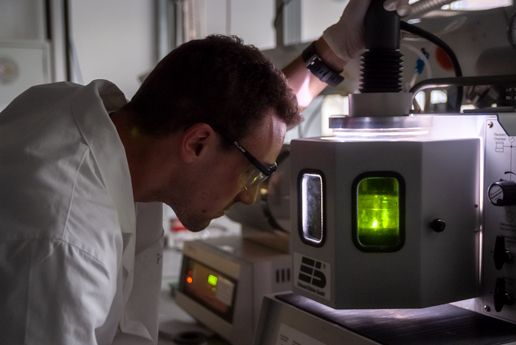

The outstanding research at the Functional Materials group of TU Darmstadt for the substitution of critical raw materials and materials for energy technologies has been recognized by honoring Prof. Dr. Oliver Gutfleisch with ERC Advanced Grant COOL INNOV.

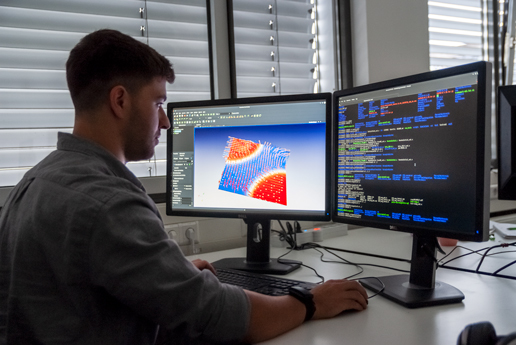

COOL INNOV will attempt to achieve a breakthrough in caloric cooling based on magnetocaloric materials by rethinking the whole concept of this technology. Instead of the conventional idea of squeezing the best out of magnetostructural phase-change materials in relatively low magnetic fields, a second stimulus introduced in the form of pressure can help the COOL INNOV team to exploit, rather than avoid, the hysteresis that is inherent in these materials. It should lead to more efficient refrigeration, with a commercially viable technology that could satisfy the urgent global need.

COOL INNOV received funding from the European Research Council (ERC) under the European Union's Horizon 2020 research and innovation program (grant no. 743116 - project Cool Innov).

COOL INNOV will attempt to achieve a breakthrough in caloric cooling based on magnetocaloric materials by rethinking the whole concept of this technology. Instead of the conventional idea of squeezing the best out of magnetostructural phase-change materials in relatively low magnetic fields, a second stimulus introduced in the form of pressure can help the COOL INNOV team to exploit, rather than avoid, the hysteresis that is inherent in these materials. It should lead to more efficient refrigeration, with a commercially viable technology that could satisfy the urgent global need.

COOL INNOV received funding from the European Research Council (ERC) under the European Union's Horizon 2020 research and innovation program (grant no. 743116 - project Cool Innov).

News

Poster Award

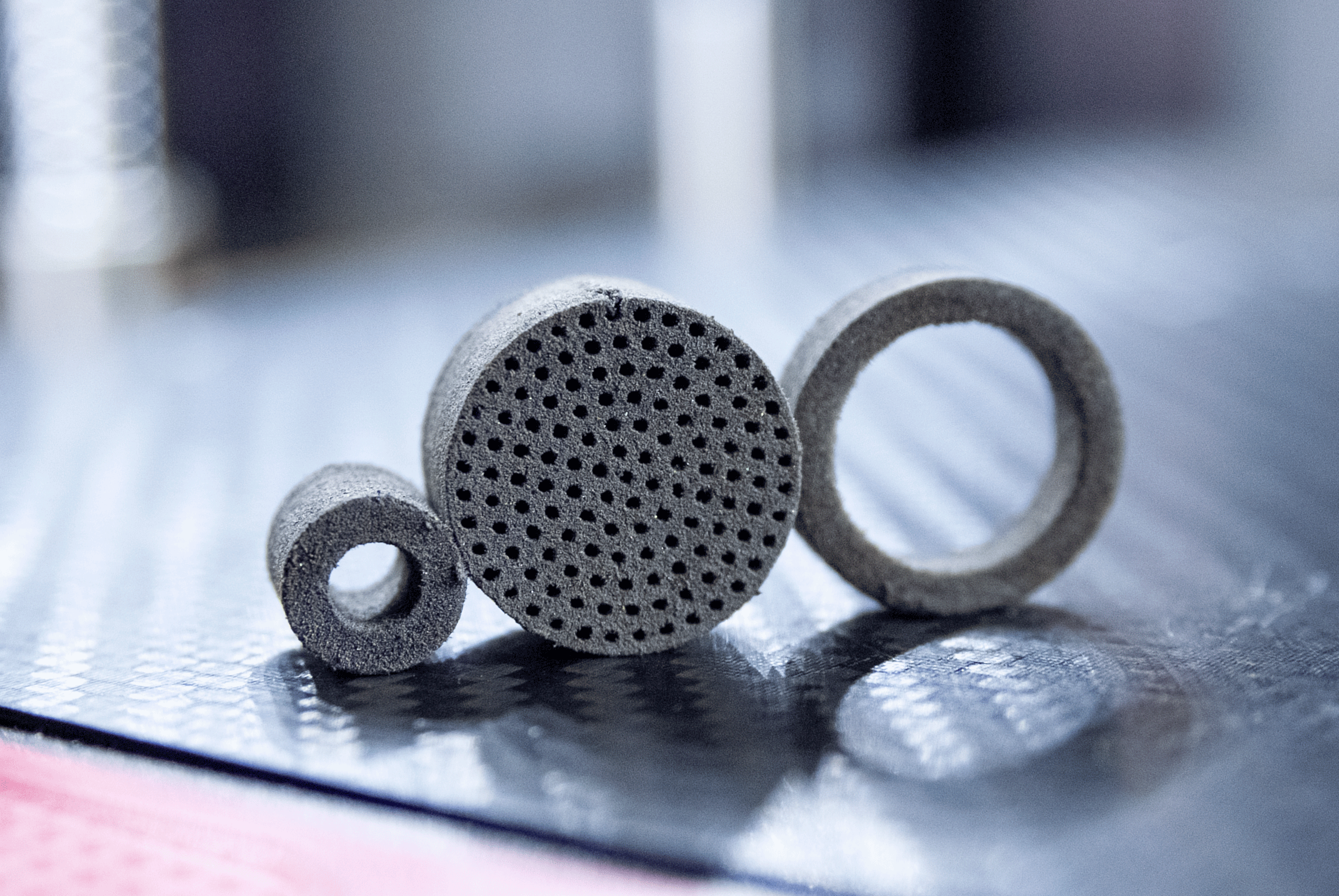

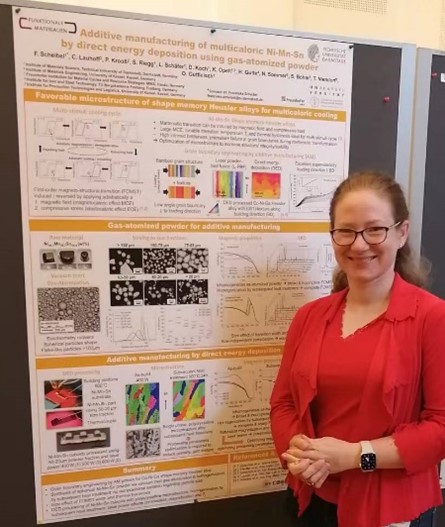

Poster Award Additive manufacturing of multicaloric Ni-Mn-Sn by direct energy deposition using gas-atomized powder

We congratulate our colleague Dr. Franziska Scheibel to the Poster Award at the international Conference “New Frontiers in Materials Design for Laser Additive Manufacturing”. A wonderful recognition for the great cooperation with our colleagues from the University of Kassel, TU Bergakademie Freiberg and Fraunhofer IWKS.

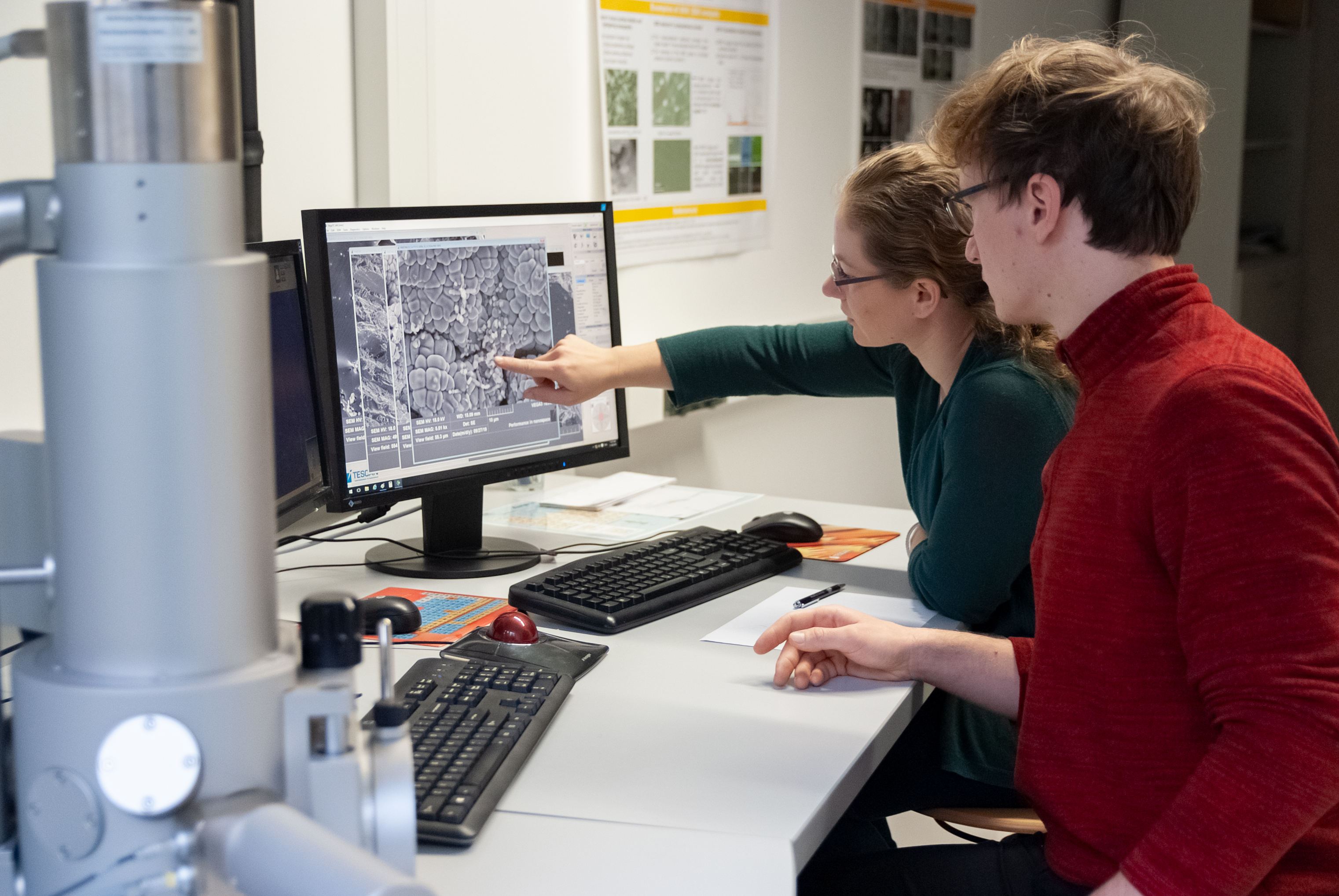

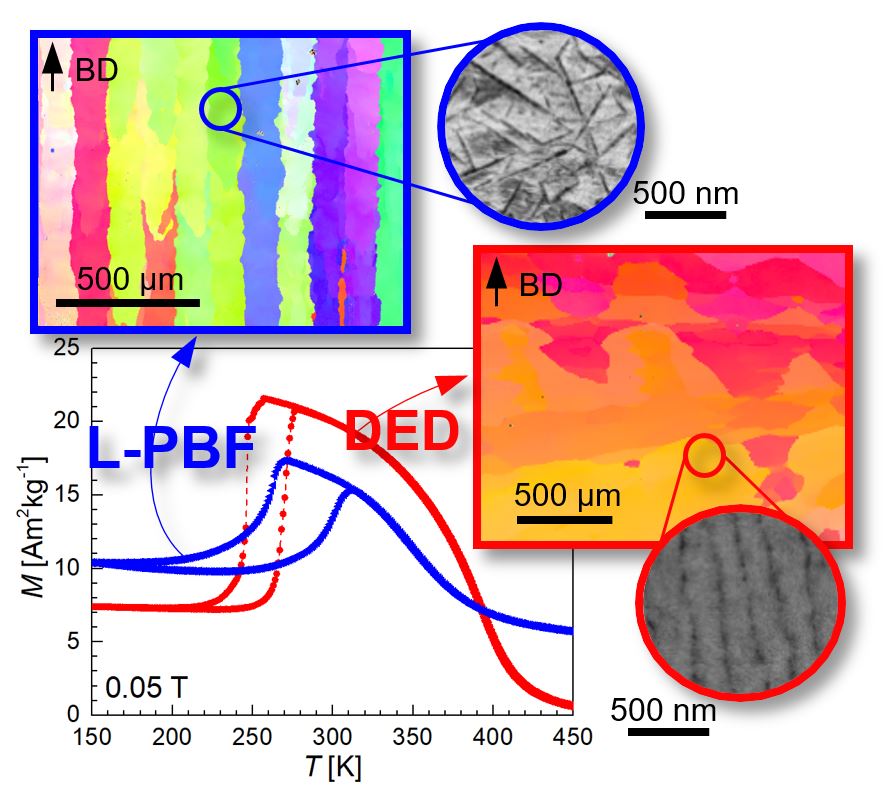

On the Impact of Additive Manufacturing Processes on the Microstructure and Magnetic Properties of Co–Ni–Ga Shape Memory Heusler Alloys

On the Impact of Additive Manufacturing Processes on the Microstructure and Magnetic Properties of Co–Ni–Ga Shape Memory Heusler Alloys Microstructure design of Co-Ni-Ga shape memory alloys by additive manufacturing can be used to prevent intergranular cracking and premature failure. The comparison of microstructure, composition and magnetic properties of Co-Ni-Ga Heusler alloy processed by direct energy deposition and laser powder bed fusion shows large differences in terms of precipitate formation and martensitic transformation behavior.

This article by Franziska Scheibel, Christian Lauhoff, Stefan Riegg, Philipp Krooß, Enrico Bruder, Esmaeil Adabifiroozjaei, Leopoldo Molina-Luna, Stefan Böhm, Yury I. Chumlyakov, Thomas Niendorf, Oliver Gutfleisch is published in Advacned Engineering Materials.

DOI: https://doi.org/10.1002/adem.202200069

Acknowledged: ERC CoolInnov, CRC-TRR HoMMage