The magnetocaloric effect (MCE) has been intensively studied over the last decades and the search for materials with larger MCE continues. Different material systems like La-Fe-Si-, Fe2P-based, and Heusler alloys have been intensively studied. However, the MCE not only depends on intrinsic properties, on a next level the influence of microstructure also needs to be investigated. Magnetic stray fields, e.g., strongly depend on geometry and microstructure. Especially in materials undergoing first-order magneto-structural transitions, the arrangement of grains and their shape will influence the MCE. Going one step further and considering the multi-stimuli approach, the microstructure is also of high importance in terms of stress distribution within the sample in order to avoid stress peaks, which could damage the material during cycling.

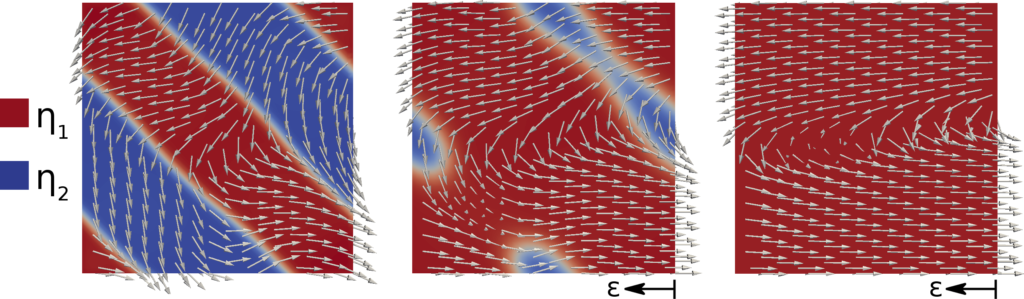

Micromagnetic simulations are based on the saturation magnetization, anisotropy and exchange stiffness of the material as initial input. These can be obtained by extended DFT calculations or from experiments. With micromagnetic simulations it is then possible to simulate the magnetization reversal process depending on a specifically generated microstructure. Besides the general investigation of the relation between microstructure and MCE, the challenge is to combine it with a model that takes into account the first-order magneto-structural phase transition, e.g. phase field models. In order to perform simulations on complex microstructures, micromagnetics are implemented using the finite element method (FEM).

The challenge for simulating our multi-stimuli cooling cycle is to combine phase field models describing the phase transition with micromagnetic formulations in order to consider magnetic field and stress induced phase transitions. Such simulations can help to optimize the MCE in future magnetocaloric cooling devices and increase the efficiency by microstructure and geometry optimization. In terms of a real device, such microstructure simulations also play an important role for the heat transfer during the multi-stimuli cycle. Overall, microstructure dependent simulations are meant to bridge the gap between DFT calculations on an atomic scale and the engineering of a real cooling device.